Recent Tapmatic Advertising

Customer Testimonials

On Tapmatic Constant Speed, Self-Reversing Heads For CNC Machining & Turning Centers

RESULTS:$15,000.00 COST SAVINGS BASED ON 15-TO-30-MINUTE-PER- PART TIME SAVINGS. Installing Tapmatic RDT50 Self-Reversing Tapping Attachment saved CNH $15,000 by eliminating secondary operation for tapping, thereby cutting production time by 15 to 30 minutes per part.

CNH AMERICA LLC

Manufacturing New Holland and Case IH

round & square hay balers

New Holland, PA.

Paul Frantz, Day-Shift Operator

Jeff Morgan, Night-Shift Operator

“Tapmatic NCRT Cuts Cycle Time In Half- 30 seconds floor to floor. Only one operation was required to complete job. 250 plates completed in 2 hours, 2 threads in each plate, 125mm center distance. Eliminating machine reversal resulted in reduced machine wear and tear.”

Mr. David Matthew

Soken Engineering Ltd.

Sub-Contract Machining and Manufacturer of Heat Sealing Equipment

England

“Tapmatic RDTIC Cut Cycle Time In Half, Increased Tap Life 300% And Reduced Machine Spindle Wear By Eliminating Machine Reversal. Cycle time for 68 holes was reduced from 6 minutes 34 seconds to 3 minutes 12 seconds for a savings of 3 minutes 22 seconds. Cycle time for 64 holes was reduced from 5 minutes 58 seconds to 2 minutes 59 seconds for a savings of 2 minutes 59 seconds. Tapmatic increased tap life from 3000 holes per to 9000 holes per tap.”

Mr. Stefan Rolke, Owner

Firma Sted GmbH

Germany

On Tapmatic SynchroFlex Rigid Tap Driver:

“Tamatic SynchroFlex Increased Tap Life From 72 Holes Per Tap To 216 Holes Per Tap. Tap Costs Reduced from $77.00 to $25.00 per day and production increased from not changing taps so often. SFT50 paid for itself in 7 days in tap cost savings alone.”

Mr. Sean Zeise, Vice President

Ziese Products Inc.

Cookson, Oklahoma USA

“Tapmatic SFT Increased Tap Life By 100 to 150% With Much Better Quality Threads. Threads consistently gage correctly eliminating time consuming re-work.”

Mr. Karl Stickel,

Criterion Machine Works,

Costa Mesa, California USA

“We’ve used our TAPMATIC 30X and other TAPMATIC heads reliably for about 25 years. This is the first time in 25 years that it has required any service. The service was extremely reasonably priced. They are wonderful tools.”

Edward J. Delzani, Owner

Delzani Industries Inc.

Job Shop and Motorcycle Repair

Rocky River, Ohio USA

“I´ve got 10 various Tapmatic units and am a little more impressed with them every day.Finest thing since sliced bread. We can´t operate without them. I often wonder how we ever produced enough product to sell and make a living before our discovery of your product. The inventor deserves world recognition. Thanks for a wonderful product.”

Darryl Barnett

Kellar Manufacturing Inc.

Grovetown, Georgia USA

“During a 4 year period this 50X tapping head tapped 20,000–pieces a week of a powdered metal part with a 7/16″ x 12 stub acme double lead x 1″ through, at a production rate of 520- pieces per hour for an approximate total of 3,500,000 to 4,000,000-pieces. The tapping head was then put into service again to tap 1/2″ x 12 double lead x 1.060 through in 11L17 material, of which we completed 4-orders each of 50,000-pieces. At no time has this 50X head had any maintenance or work done to it, and we still continue to use it.”

M.R. Bowen, President

Bil-Mac Corporation

Grandville, Michigan USA

“As a machine job shop, we have kept our Tapmatic 30TC/DC busy as an every day tool for about 6 years without a lick of trouble. We have no idea how many tens or hundreds of thousands of holes it has tapped. We also own SPD3 and 50 TC/DC models.”

Kenneth A. Regas, Owner

Balboa Products,

San Diego, California USA

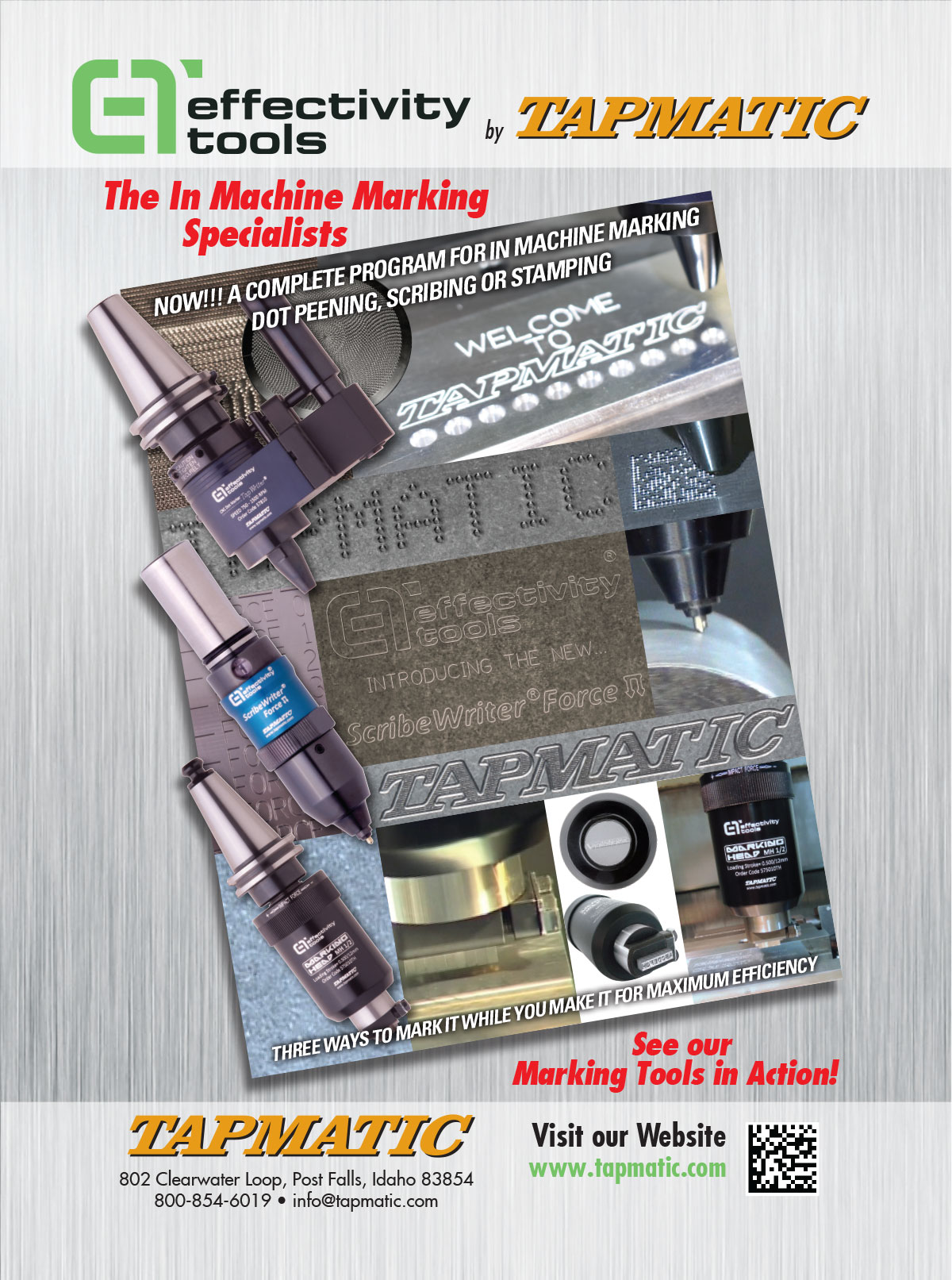

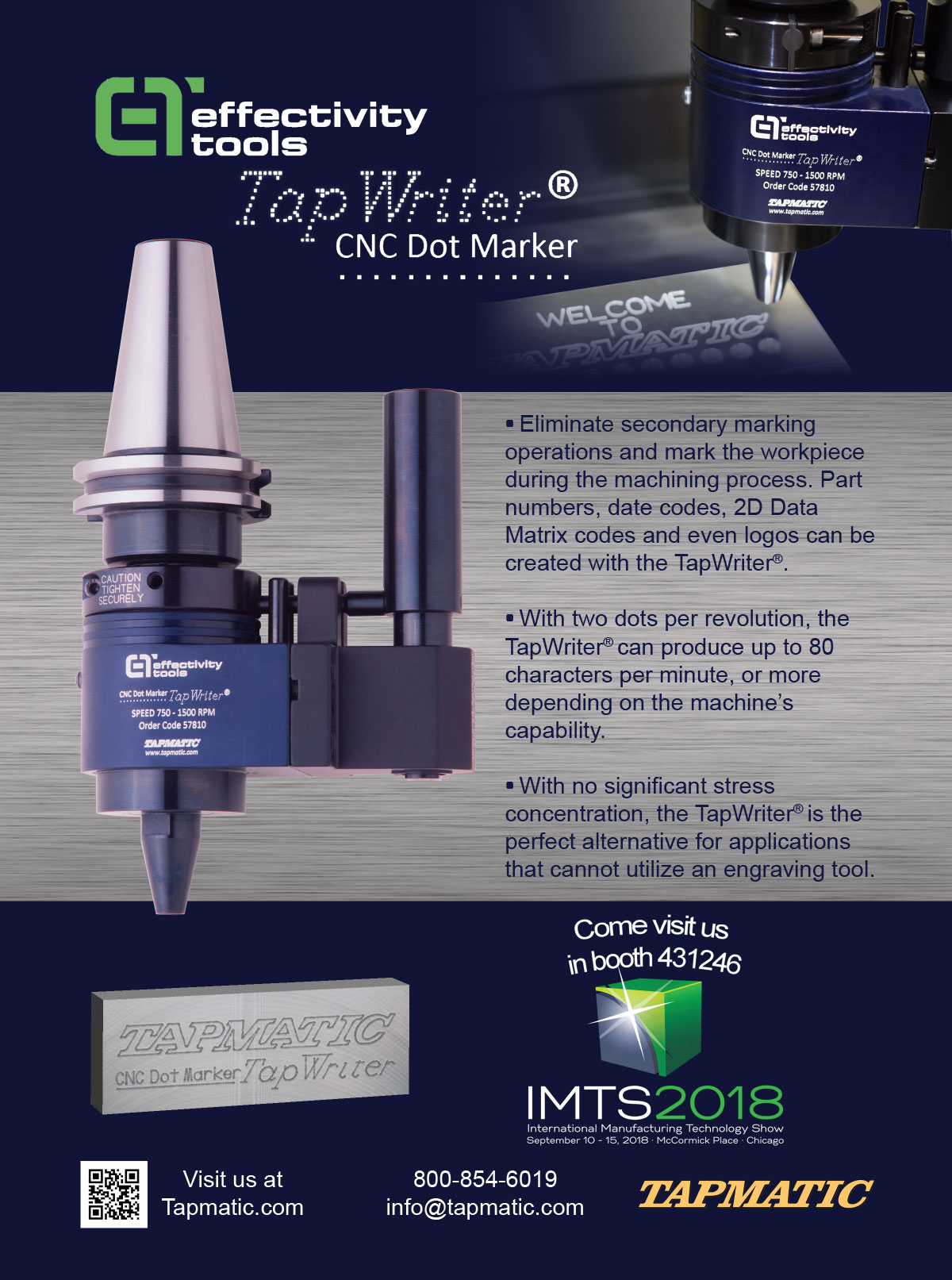

TapWriter - Mark It While You Make It

New Scribewriter marks material hardened up to 60 HRc

Southeast Manufacturing Series

October 21-23

Please visit our booth 1936