|

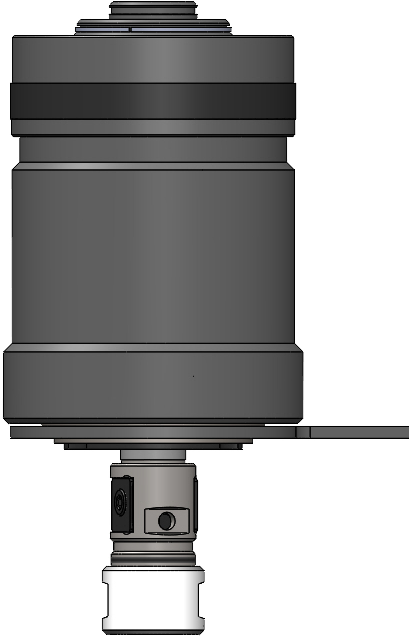

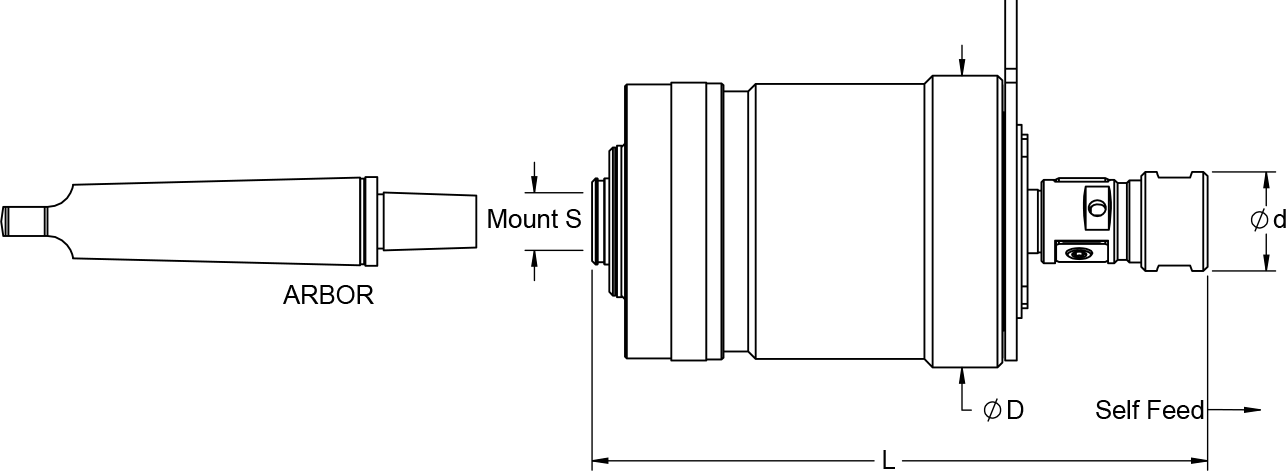

RxII Tapping Heads with High-Speed Reverse, Torque Control, and Rubber-Flex Collet

(Dimensions in mm)

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Description | Tap Sizes | Mount S | Collets | D | d | L | Self Feed | MAX RPM | Order Code | Quote |

| RX II 30, #6JT, 21 Series | M1.4-M7 ● #0-1/4" | #6JT | 21 Series | 53 | 19 | 116 | 3 | 2000 | 11406 | |

| RX II 30, DIN B16, 21 Series | M1.4-M7 ● #0-1/4" | DIN B16 | 21 Series | 53 | 19 | 116 | 3 | 2000 | 11416 | |

| RX II 30, #33JT, 21 Series | M1.4-M7 ● #0-1/4" | #33JT | 21 Series | 53 | 19 | 116 | 3 | 2000 | 11433 | |

| RX II 30, 1/2"-20 THD, 21 Series | M1.4-M7 ● #0-1/4" | 1/2"-20 THD. | 21 Series | 53 | 19 | 116 | 3 | 2000 | 11450 | |

| RX II 50, #6JT, 22 Series | M3-M12 ● #6-1/2" | #6JT | 22 Series | 80 | 27 | 169 | 5 | 1500 | 116006 | |

| RX II 50, DIN B16, 22 Series | M3-M12 ● #6-1/2" | DIN B16 | 22 Series | 80 | 27 | 169 | 5 | 1500 | 116016 | |

| RX II 50, #33JT, 22 Series | M3-M12 ● #6-1/2" | #33JT | 22 Series | 80 | 27 | 169 | 5 | 1500 | 116033 | |

| RX II 50, 7/8"-20 THD, 22 Series | M3-M12 ● #6-1/2" | 7/8"-20 THD | 22 Series | 80 | 27 | 164 | 5 | 1500 | 116087 | |

| RX II 70, #3JT, 24 Series | M5-M18 ● #10-3/4" | #3JT | 24 Series | 88 | 37 | 182 | 7 | 1200 | 11803 | |

| RX II 70, 7/8"-20 THD, 24 Series | M5-M18 ● #10-3/4" | 7/8"-20 THD | 24 Series | 88 | 37 | 182 | 7 | 1200 | 11887 | |

|

90xII Tapping Head with High-Speed Reverse, Torque Control, and Rubber-Flex Collet

(Dimensions in mm)

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Description | Tap Sizes | Mount S | Collets | D | d | L | Self Feed | MAX RPM | Order Code | Quote |

| 90XII, #4JT, 26 Series | M10-M30 ● 1/2"- 1 1/8" | #4JT | 26 Series | 105 | 57 | 219 | 13 | 600 | 11904 | |

| 90XII, 1 1/2"-18 THD, 26 Series | M10-M30 ● 1/2"- 1 1/8" | 1 1/2-18 THD | 26 Series | 105 | 57 | 219 | 13 | 600 | 11915 | |

|

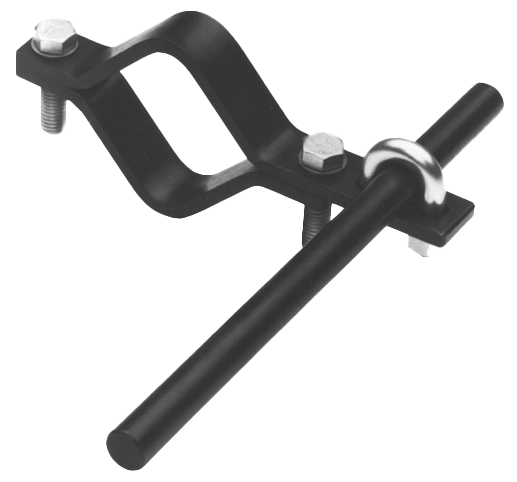

Quill Mount Torque Bars

|

||||

|---|---|---|---|---|

| Description | For Max Tap Size | Fits Quill Diameters | Order Code | Quote |

| Small Quill Mount Torque Bar | M16 or 1/2" | 38-60mm or 1 1/2"-2 3/8" | 29099 | |

| Large Quill Mount Torque Bar | M18 or 3/4" | 60-114mm or 2 3/8"-4 1/2" | 290991 | |

|

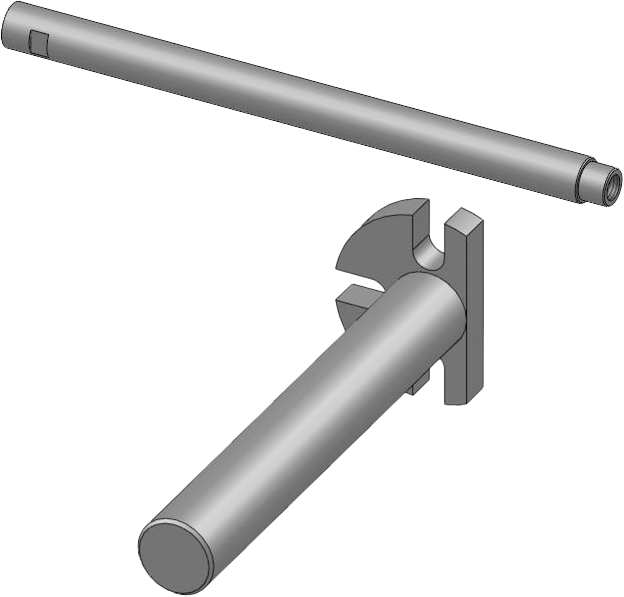

Table Mount Torque Bars

|

|||

|---|---|---|---|

| Description | For Max Tap Size | Order Code | Quote |

| Large Table Mount Torque Bar | M33 or 1 3/4" | 29096 | |

| Table Mount Torque Bar | M18 or 3/4" | 29097 | |

|

Torque Bar Mounting

|

|

|---|---|

| Always mount a torque bar to hold the tapping attach-ment’s stop arm from rotating. The torque bar must be mounted securely to the table or quill of the machine. The installation must be stronger than the largest tap in the capacity range of the tapping attachment. Please see complete instructions provided with tapping head. |

|