STAMPING

Stamp your mark on the work piece

in less than a second.

in less than a second.

If the work piece surface is flat, and the size of the text you need to imprint is within a 40mm length, stamping is the fastest method. You can hold standard type or a custom stamp to imprint a variety of characters, logos or symbols.

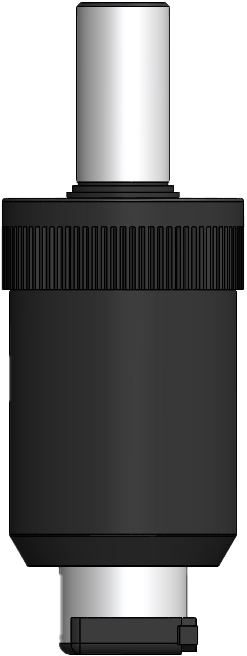

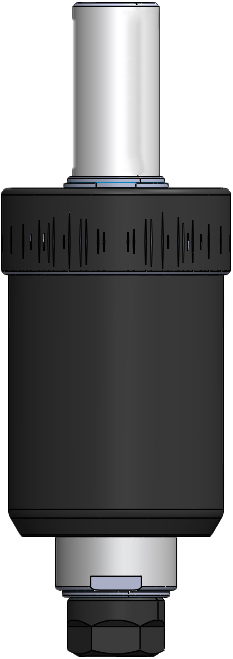

With our MH series marking heads, no rotation is used, the machine compresses the head against the work piece, 12mm for the MH 1/2 and 18mm for the MH 3/4. This compression charges and launches the inertia system creating the impact that stamps the part. After compression simply rapid away. The marking head\'s shock absorption system cushions any recoil effect on the machine spindle or turret.

- Eliminates the need for secondary marking operations.

- Type holder version holds standard type or custom stamps.

- ER collet version holds round shank stamps.

- Simple to install on any machine including CNC mills and lathes and even conventional machines.

- Shock absorption system prevents any recoil effect on the machine spindle or turret.

- Marking force is fully adjustable.