Suggested Percentage Of Full Threads In Tapped Holes

It stands to reason that it takes more power to tap to a full depth of thread than it does to tap to a partial depth of thread. The higher the metal removal rate, the more torque required to produce the cut.

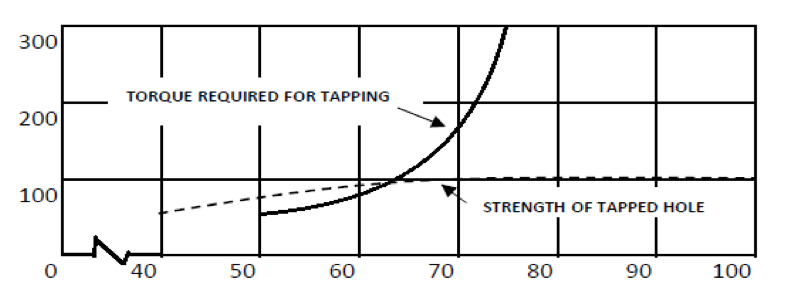

It would also stand to reason that the greater the depth of thread, the stronger the tapped hole. This is true, but only to a point. Beyond that point (usually about 75% of full thread) the strength of the hole does not increase, yet the torque required to tap the hole rises exponentially. Also, it becomes more difficult to hold size, and the likelihood of tap breakage increases. With this in mind, it does not make good tapping sense to generate threads deeper than the required strength of the thread dictates.

As a general rule, the tougher the material, the less the percentage of thread is needed to create a hole strong enough to do the job for which it was intended. In some harder materials such as stainless steel, Monel, and some heat-treated alloys, it is possible to tap to as little as 50% of full thread without sacrificing the usefulness of the tapped hole.

| Workpiece Material |

Deep Hole Tapping |

Average Commercial Work |

Thin Sheet Stock Or Stampings |

| Hard or Tough Cast Steel Drop Forgings Monel Metal Nickel Steel Stainless Steel |

55% - 65% | 60% - 70% | - |

| Free-Cutting Aluminum Brass Bronze Cast Iron Copper Mild Steel Tools Steel |

60% - 70% | 65% - 75% | 75% - 85% |